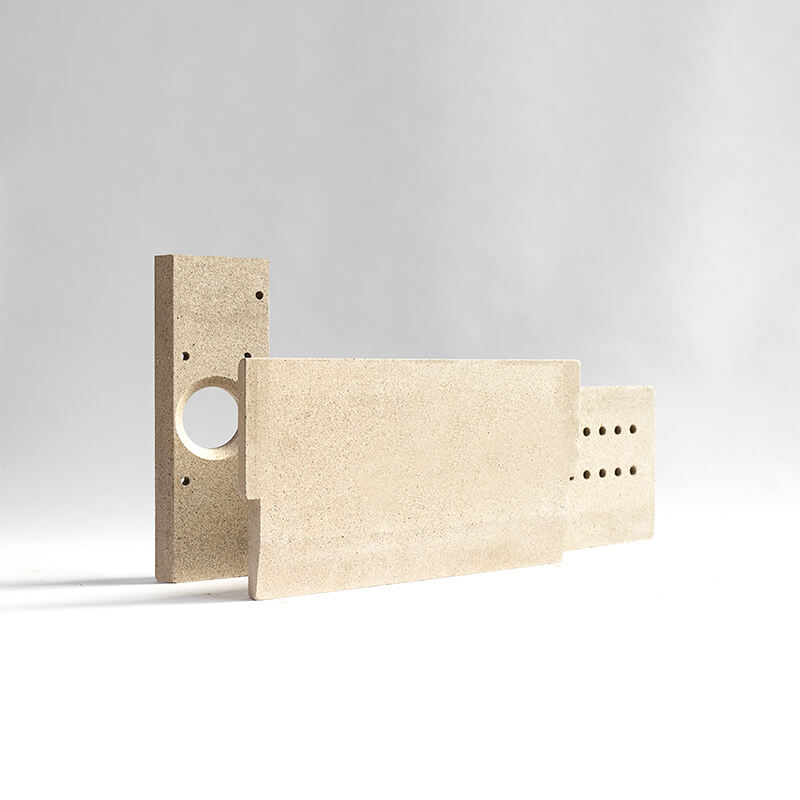

Bitwater (Shenzhen) Technology Co., Ltd.’s high temperature insulating bricks find extensive applications in industries requiring reliable thermal management under extreme conditions. In aluminium electrolytic cells, these bricks withstand the intense heat and corrosive effects of electrolytes, preserving cell efficiency and extending equipment life. For industrial furnaces used in steelmaking, ceramics, and heat treatment, high-density (500 kg/m³) bricks form durable linings that resist thermal shock and maintain precise temperature control, improving product quality and reducing energy waste. In condensing gas boilers, low-density (400 kg/m³) bricks minimize heat loss, enhancing energy efficiency by up to 35% while reducing system weight. Fireplaces and wood-burning stoves benefit from their fireproof properties and aesthetic versatility, while kilns and ovens rely on their dimensional stability for consistent processing. These applications highlight the bricks’ adaptability across diverse sectors, combining insulation performance with operational resilience.The bluewind vermiculite lightweight insulating brick serves a distinct purpose as it is engineered for the purpose of being used in industrial furnaces while dealing with high temperatures. Its inclusion of non asbestos expands silver vermiculite makes it possible for the composition of the controlling and uniform pore structure to be used in order to effectively act as an insulator. These bricks can easily be lined for transition or refractorily as back up insulation to improve the way the industrial furnace works and can make it last longer. The ultimate low thermal mass performance of our heating performing fire bricks is made possible through advanced manufacturing techniques involving compression and sintering under extreme temperatures.