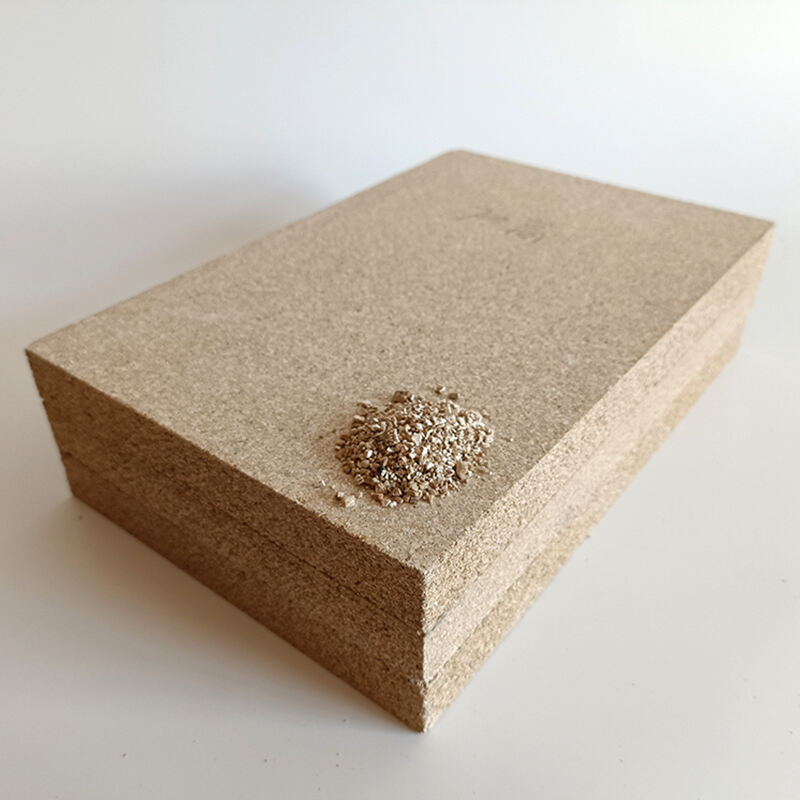

Firebrick insulation techniques for industrial furnaces are essential for optimizing thermal efficiency, reducing energy consumption, and ensuring the longevity of furnace components. Bitewater (Shenzhen) Technology Co., Ltd. employs advanced insulation techniques using high-quality firebricks to create effective thermal barriers within industrial furnaces. One key technique involves the strategic placement of firebricks in layers, with each layer serving a specific purpose in heat retention and distribution. The innermost layer, typically made of high-density firebricks, directly withstands the intense heat generated by the furnace, protecting the outer structure from damage. Intermediate layers of insulating firebricks with lower thermal conductivity help minimize heat loss, while the outermost layer provides additional insulation and structural support. Another technique involves the use of anchoring systems to secure the firebricks in place, preventing movement or shifting due to thermal expansion and contraction. This ensures consistent performance and reduces the risk of heat leakage. Additionally, Bitewater incorporates advanced materials such as vermiculite-based insulation into their firebrick systems to enhance thermal efficiency and fire resistance. These techniques, combined with the company's expertise in custom system solutions, enable industries to achieve significant energy savings, improved operational efficiency, and enhanced safety in their furnace operations.