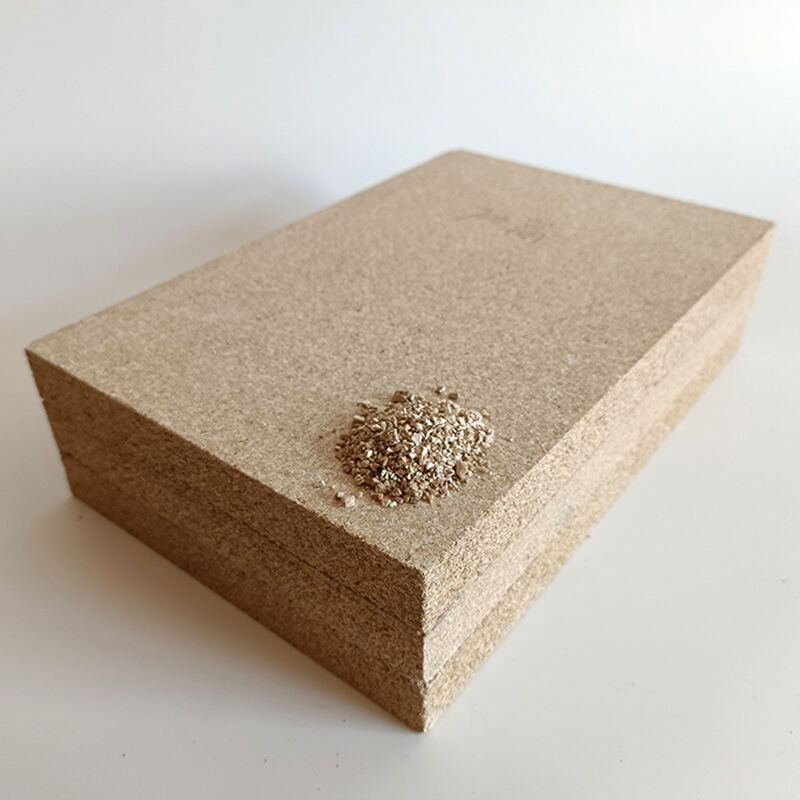

The Vermiculite Brick Sintering Process is the most important stage in the production of our high-performance insulating fire bricks. This process requires the proper compression of expanded silver vermiculite and inorganic fillers and then sintering at high temperatures. This approach improves the physical characteristics of the bricks’ material and helps to obtain a favorable porous structure through which insulation can be achieved. Therefore our vermiculite bricks are extensively used in diverse industrial furnaces in order to serve as transition refractory linings or backup insulation which helps to improve service life and thermal efficiency substantially.