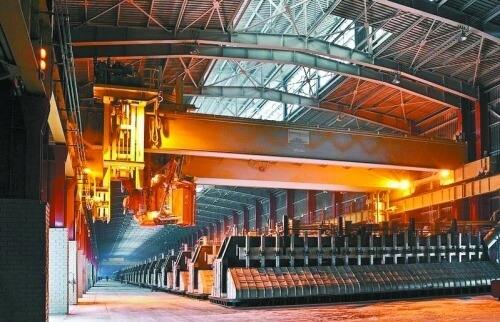

الطوب الحراري، المعروف أيضًا باسم الطوب المقاوم للحرارة، هو مواد سيراميكية متخصصة مصممة لتتحمل درجات الحرارة المرتفعة للغاية دون الانصهار أو التدهور. تتنوع تطبيقات الطوب الحراري وتعد ضرورية في مختلف الصناعات، وخاصة تلك التي تتضمن عمليات حرارية عالية. في صناعة الصلب، يُستخدم الطوب الحراري لتبليط داخل الأفران والصهاريج والمُحوِّلات، مما يحمي سلامة هيكل المعدات ويضمن احتفاظ الحرارة بكفاءة أثناء صهر المعادن وتنقيتها. وبالمثل، تُستخدم الطوب الحراري في قطاع الألومنيوم داخل أفران الصهر والاحتفاظ لضمان الحفاظ على درجات الحرارة المثلى للألمنيوم المنصهر. تعتمد صناعة معدات التدفئة والتبريد، بما في ذلك المواقد والأفران الصناعية، بشكل كبير على الطوب الحراري لصنع غرف احتراق آمنة وفعالة يمكنها تحمل التعرض الطويل للهب والحرارة الشديدة. وفي قطاع البناء، يُستخدم الطوب الحراري في المواقد ومواسير الدخان والهياكل المقاومة للحريق الأخرى لتقديم مقاومة للحريق ومنع انتشار اللهب في حالة حدوث حريق. علاوةً على ذلك، يُستخدم الطوب الحراري في تصنيع الزجاج وإنتاج الإسمنت والمحارق، حيث تكون المقاومة العالية للحرارة ضرورية. تخصصت شركة Bitewater (Shenzhen) Technology Co., Ltd. في توفير طوب حراري عالي الجودة مصمم لتلبية الاحتياجات المحددة لهذه الصناعات، مما يضمن الأداء الأمثل والسلامة والمتانة حتى في أكثر الظروف تحديًا.