The Critical Role of Thermal Insulation in Modern Industrial Facilities

For the efficient operation of contemporary industrial setups, thermal insulation is crucial. Advanced insulation systems cut energy consumption by as much as 30% in high-temperature processes, such as smelting metal or synthesising chemicals, by limiting heat transfer through machinery and structural components. This reduces operating costs directly, while maintaining worker safety in dusty, hot environments where the surface temperature can reach up to 150°C.

The strategic implementation of insulation also stabilizes production conditions—critical for industries like pharmaceuticals and food processing that require precise temperature control. Optimized insulation in piping systems prevents significant energy leakage, with recent studies highlighting savings equivalent to powering 12,000 homes annually.

How Contemporary Solutions Meet the Dual Demands of Construction and Industrial Sectors

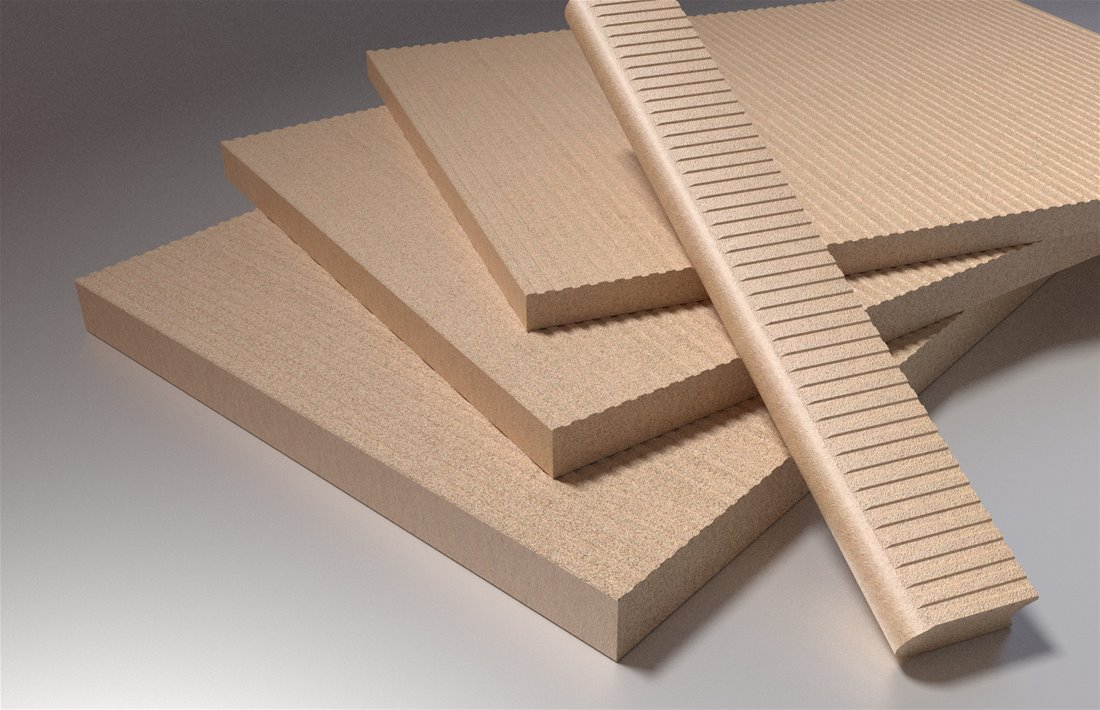

Modern insulation materials bridge sector-specific needs through adaptive design:

- Construction: Enhances building envelope performance, reducing HVAC loads by 25–40% in commercial structures

- Industrial: Withstands extreme temperatures (from -200°C to 1200°C) in refinery pipelines and reactor vessels

Peer-reviewed research demonstrates 18% better thermal resistance than legacy options like fiberglass. Modular formats allow seamless integration into curved surfaces and complex joints—a frequent challenge in both factory retrofits and new builds.

Energy Efficiency and Regulatory Compliance Across Applications

Global standards like ASHRAE 90.1 and ISO 50001 mandate minimum insulation thicknesses for industrial equipment and building interiors. High-performance solutions help facilities exceed these requirements while achieving 35–40% reductions in annual carbon emissions.

In cold storage warehouses, proper insulation reduces refrigeration energy demands by up to 60%, directly supporting LEED certification goals. Material flammability ratings (Class A fire resistance) and VOC-free compositions further address tightening environmental regulations.

Real-World Performance: Industrial Applications

Case Study: Energy Efficiency Gains in Automotive Manufacturing

A major automotive production facility reduced HVAC-related energy consumption by 22% after installing advanced thermal insulation. By maintaining consistent temperatures in paint-curing ovens and battery-testing chambers, the plant achieved annual energy savings of $410,000—supporting lean manufacturing principles while meeting emissions standards.

Food Processing Facilities Achieve Safety and Efficiency

Temperature-sensitive food production lines require precision thermal control to prevent spoilage. Specialized insulation reduces temperature deviations by 35% compared to traditional materials—critical for minimizing microbial growth risks in meat processing and dairy operations.

Chemical Plants Reduce Heat Loss

High-temperature reactors in chemical manufacturing achieve unprecedented thermal retention. Petrochemical sites using upgraded insulation reduced steam system heat loss by 38–42%, equivalent to recovering $2.8 million annually in wasted energy.

Customer Retention and ROI

A 2024 survey found 81% of manufacturers recouped insulation upgrade costs within 18 months through reduced utility bills—contributing to a 97% retention rate among industrial clients.

Comparative Analysis: Millegap vs. Polyurethane and Mineral Wool

| Material | Thermal Resistance (R-Value/inch) | Long-Term Cost/SF (20 yrs) | Fire Safety Rating |

|---|---|---|---|

| Polyurethane Foam | 5.8 | $9.20 | Class B |

| Mineral Wool | 4.1 | $11.50 | Class A |

| Millegap | 8.3 | $7.80 | Class A+ |

Independent testing reveals Millegap maintains 94% thermal stability at 700°F versus polyurethane's 62% degradation at 450°F. Facilities using advanced materials achieve 23% faster regulatory compliance through unified thermal/fire performance standards.

Dual Thermal and Acoustic Insulation Benefits

The integration of thermal insulation with acoustic control capabilities is revolutionizing industrial facility design:

- Automotive plants reduce ambient noise by 63% while maintaining stable temperatures

- OSHA data shows 41% fewer noise-related incidents after insulation upgrades

Innovative systems combine aerogel matrices with sound-dampening layers to achieve:

| Property | Traditional Materials | Advanced Systems |

|---|---|---|

| Thermal Resistance | 3.5–4.0 per inch | 6.2–7.1 per inch |

| Noise Reduction (NRC) | 0.35–0.55 | 0.75–0.85 |

This architecture enables 82% faster installation times compared to separate treatments while meeting all safety requirements.

Market Trends and Millegap's Strategic Position

The thermal insulation industry is projected to grow at 6.5% CAGR through 2030, with industrial applications accounting for 38% of global demand. Key drivers include:

- Stricter emissions standards

- 25-40% energy cost savings

- Renewable energy infrastructure expansion

Millegap maintains competitive advantages through:

- Higher R-values per inch (40% improvement vs. mineral wool)

- Corrosion-resistant composition

- 100% non-combustible properties

Over 500 large-scale installations since 2020 demonstrate:

- 0.3% annual thermal degradation

- 93% recycled material content

- 30-year lifecycle cost reductions

This positions the technology as a frontline solution for industries transitioning to net-zero operations.

FAQ

What role does thermal insulation play in industrial settings?Thermal insulation minimizes heat transfer, improving energy efficiency and maintaining worker safety in high-temperature processes.

How does insulation benefit construction and industrial sectors differently?In construction, insulation reduces HVAC loads. In industrial sectors, it withstands extreme temperatures and minimizes energy leakage.

How is insulation linked to environmental compliance?Insulation helps meet global standards for energy savings and reduces carbon emissions, supporting environmental goals.

What are the advantages of using materials like Millegap?Millegap offers high thermal resistance, low cost, and superior fire safety, making it advantageous for long-term use.

How does insulation impact noise levels?Integration of thermal and acoustic insulation reduces ambient noise significantly, improving workplace conditions.

Table of Contents

- The Critical Role of Thermal Insulation in Modern Industrial Facilities

- How Contemporary Solutions Meet the Dual Demands of Construction and Industrial Sectors

- Energy Efficiency and Regulatory Compliance Across Applications

- Dual Thermal and Acoustic Insulation Benefits

- Market Trends and Millegap's Strategic Position

- FAQ