Thermal Performance of Vermiculite in High-Temperature Applications

How Vermiculite's Mineral Structure Enhances Heat Resistance

The special way vermiculite is built at the mineral level gives it great thermal insulation properties, particularly where temperatures get really high. When heated, this layered silicate mineral expands dramatically, forming tiny air pockets throughout its structure. These little gaps act as natural insulators, helping the material block heat from moving through it. Research shows vermiculite actually works better than common alternatives like fiberglass or foam insulation in super hot conditions because of how it expands. For sectors dealing with serious heat issues, like aerospace manufacturing or steel mills, this heat resistance makes vermiculite almost essential. Companies working with extreme temperatures find that using vermiculite helps control thermal stress much better than other options, which ultimately improves safety across their operations in those demanding environments.

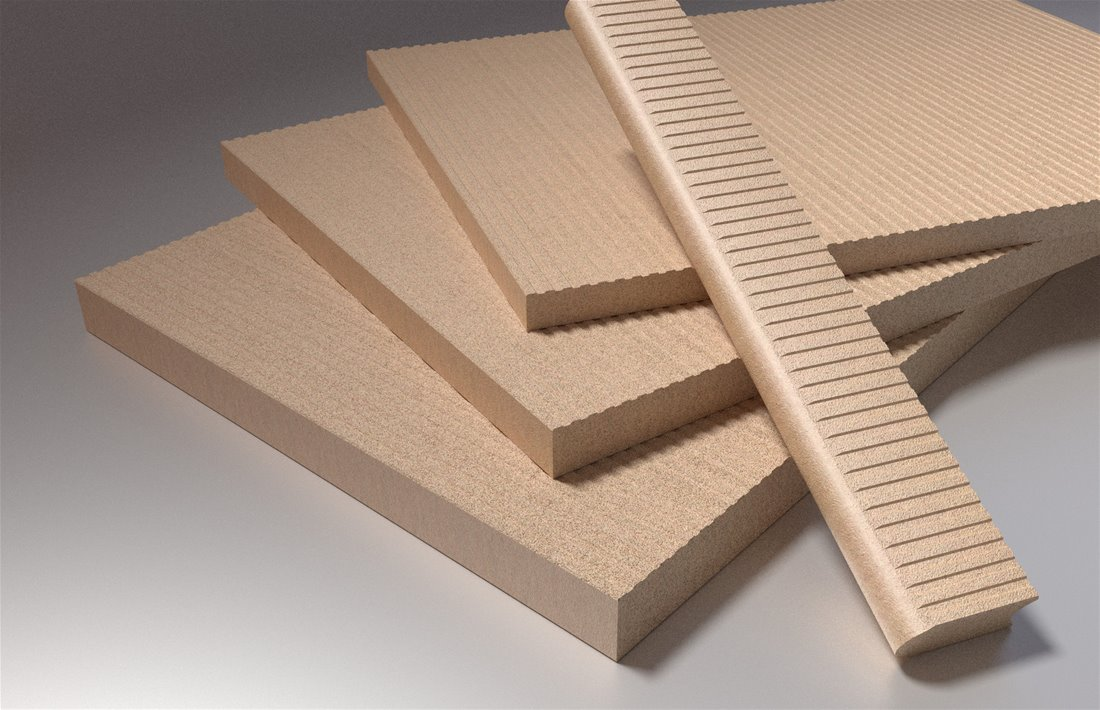

Comparing Vermiculite Board to Traditional Industrial Insulation Materials

When it comes to industrial insulation, vermiculite boards stand out compared to older options like mineral wool or polystyrene. They have much better thermal properties, so they keep heat where it needs to be. Plus, these boards are light enough to handle without special equipment, which cuts down on installation time and money spent on labor. What really matters for long term performance is how well they hold up against water damage and mold growth. Vermiculite resists these issues pretty well, which explains why many factories still specify them for areas with extreme temperatures according to building codes. From an environmental standpoint, switching to vermiculite makes sense too. Since it's made from natural minerals rather than plastics, there's less impact on resources during production. Factories looking to cut energy bills while meeting green initiatives often find themselves turning back to this old reliable material despite all the newer alternatives on the market.

Non-Combustible Properties for Hazardous Environments

The fact that vermiculite doesn't burn makes it a real asset for fire safety in places like chemical plants where sparks can be deadly. When exposed to actual flames, this stuff just sits there without catching fire, which cuts down on potential disasters in locations where combustion is always a risk. Some studies have actually shown that buildings insulated with vermiculite tend to have far fewer fire problems than ones using traditional insulation materials. What sets vermiculite apart is how it holds up structurally even during intense fires. Many other insulating products start breaking down or worse, release dangerous gases when heated. Industry certifications back up these claims about vermiculite's fire resistance properties, making it a go-to choice for manufacturers dealing with serious fire risks daily. For companies operating in high hazard zones, choosing vermiculite insulation isn't just about feeling safe—it meets all those tough regulatory requirements too.

Meeting Modern Building Codes and Safety Regulations

Vermiculite insulation satisfies most current fire safety regulations in places like California and New York, which makes it a good choice for buildings that need to follow strict rules. Building codes really matter here because if someone picks cheap or poor quality insulation instead, there could be serious problems down the road. People might get hurt or lose their homes. Fire marshals actually recommend stuff like vermiculite specifically because it handles heat so well. Look at warehouses and factories that have switched to this material recently they're passing inspections without any trouble while keeping workers safe. Using vermiculite isn't just about following laws either. It helps reduce waste over time since it lasts longer than many alternatives, plus it keeps everyone inside protected from potential fires, which is pretty important when thinking about real estate investments these days.

Thermal Regulation for Reduced HVAC Demands

Vermiculite insulation helps keep indoor temperatures steady, which means people don't need to run their heating and air conditioning systems as much. What makes this material special is how it handles heat transfer at high temperatures, cutting down on both heating costs during winter months and cooling expenses when summer hits. Real world testing shows pretty impressive results too. A warehouse in Minnesota saw their monthly electricity bill drop after switching to vermiculite, while an apartment complex in Texas reported similar savings despite extreme temperature swings. For homes and factories alike, keeping those temperatures consistent isn't just good for comfort but actually saves money over time. Some research indicates buildings using vermiculite instead of conventional options might save around 30% on energy bills. Of course, actual savings depend on many factors including local climate conditions and building design specifics.

Long-Term Cost Savings in Commercial Facilities

Putting vermiculite insulation into place at commercial buildings often pays off big time down the road. Sure, the upfront costs might look steep compared to other options, but most facility managers find that their monthly energy tabs drop noticeably within a year or so. Plus, there's less need for repairs and replacements since vermiculite stands up better to wear and tear than many alternatives. Industry insiders have been talking about these kinds of savings for years now, especially as energy rates keep climbing and new HVAC systems come onto the market. Take the case of that warehouse district in Chicago that switched to vermiculite last winter – their heating bills dropped by almost 30% during the coldest months. What really matters though is how well it holds up over decades of use. Vermiculite doesn't degrade like some materials do, so building owners don't end up spending extra money on fixes later on. For companies looking to cut costs while staying green, this kind of insulation just makes good business sense.

Best Practices for Wall Cavities and Attic Applications

Getting vermiculite installed correctly in walls and attics really makes a difference when it comes to getting the most out of its heat regulating capabilities. People love vermiculite for insulating at high temps, which is why so many builders choose it instead of heavier alternatives since it doesn't catch fire easily either. Filling those wall cavities thoroughly matters a lot if we want to stop those annoying cold drafts from forming. Same goes for attic spaces where we need to spread the stuff evenly across everything to block those pesky thermal bridges that waste energy. Working around tricky spots isn't always easy though. Uneven floors or tight corners in older homes can drive anyone crazy trying to get coverage right. That's exactly where vermiculite shines brightest because we can literally pour it into weird shaped spaces and let gravity do most of the work. A lot of folks mess up their installations by forgetting to seal properly or leaving patches thin in certain areas. Always check what the manufacturer recommends before starting any project. Most companies provide clear guidelines on how much material to use per square foot and where extra attention might be needed based on building codes in different regions.

Professional Installation vs. DIY Challenges

When it comes to installing vermiculite insulation, the choice between hiring pros or going the DIY route makes a real difference in how well the insulation works. Experienced installers know all the tricks of the trade that most homeowners wouldn't think about, things like getting every corner covered properly and using techniques that keep the insulation performing at its best year after year. The right installation matters because poor workmanship leads to gaps and cold spots that waste energy. On the flip side, many people opt for DIY since it saves money upfront, but there's a catch. Without proper knowledge, common mistakes happen all the time - stuff like leaving sections underfilled or missing seals around pipes and wires. These errors cut down on the insulation value considerably. Anyone thinking about doing it themselves should definitely check out good quality guides online and maybe watch some videos first. For folks who decide they want professional help, finding reputable contractors isn't hard nowadays. Most local hardware stores have lists of certified installers who understand what needs to be done to get vermiculite insulation working as intended.

Eco-Friendly Mineral Composition and Low Carbon Footprint

Vermiculite comes from nature itself and stands out as an environmentally friendly option when it comes to insulation work, plus it leaves behind a pretty small carbon footprint too. The process starts at the mine, which actually uses much less energy than what goes into producing synthetic insulators. This makes vermiculite's whole life cycle quite sustainable overall. Buildings insulated with this material tend to emit fewer greenhouse gases during their entire existence, something that fits right in with modern green building approaches. Many green building standards actually recognize vermiculite these days because builders want options that don't hurt the planet so bad. For anyone looking for alternatives to standard insulation products, vermiculite offers real value without compromising on performance or sustainability goals.

Contribution to LEED and Green Building Certifications

When it comes to getting those coveted LEED certifications and meeting other green building standards, vermiculite insulation really shines as an important component in sustainable construction efforts. With more builders looking for eco friendly options these days, vermiculite catches attention because it actually helps accumulate those valuable certification points. Take a look at some real world examples from LEED certified buildings around the country, and we see how well vermiculite works when incorporated properly into designs, which ultimately supports greener cities overall. The market seems to be moving in this direction too, with lots of new construction projects specifying green materials like vermiculite. Industry reports back this up, showing that companies are pouring more money into sustainable resources than ever before. Speaking of which, let's now turn our attention to something just as critical but often overlooked...

Understanding the Asbestos Connection in Historical Context

Vermiculite insulation carries quite a complicated past, especially because of worries about asbestos contamination back in the day. For decades, certain vermiculite batches did contain asbestos fibers, which posed serious health dangers for people exposed to them. Thanks to stricter regulations though, those old problems have largely disappeared from today's market. The EPA ran extensive testing programs that proved most contemporary vermiculite products don't carry any asbestos risk anymore. What we see now are materials meeting tough industry standards, so they work well across different construction scenarios. When shopping for vermiculite, always check for certification labels showing no asbestos content. These certifications aren't just paperwork formalities they actually protect workers and homeowners from potential hazards down the road.

Modern Safety Standards for Vermiculite Handling

When working with vermiculite insulation, following today's safety rules is absolutely essential for protecting everyone involved from workers on site right down to people living in buildings where it's installed. The latest safety manuals outline what needs doing correctly during handling and stress how important good installation techniques are whether in homes or factories. Many organizations now offer training courses and certifications so tradespeople know exactly what to look out for when dealing with this material. These programs keep participants informed about new safety protocols and any changes to regulations around vermiculite use, which helps maintain compliance while keeping workplaces safer overall.

Future Trends in Vermiculite-Based Insulation Solutions

Innovations in High-Temperature Insulation Products

New tech keeps changing how we make vermiculite for those really hot situations where regular materials just won't cut it. What's happening now? Manufacturers are working hard to make this stuff stand up better to extreme heat while making it work in tougher conditions too. The insulation world is moving toward mixing vermiculite with other top notch materials for better results. Some folks in the business talk about what might come next for these insulation products. They think we'll see better energy savings and maybe even new places where vermiculite can be used beyond what we know today. And honestly, this matters because besides being good at insulating, these innovations could actually help reduce environmental impact as industries try to clean up their act.

Projected Growth in Construction and Manufacturing Sectors

The market is showing real potential for vermiculite across construction and manufacturing industries right now. With more people looking for materials that can handle extreme heat, vermiculite has become quite popular because it's reasonably priced while still offering good thermal protection, something that fits well with green building initiatives. Industry reports point to expanding markets where vermiculite insulation is being adopted at an accelerating pace, mainly because buildings need to be more energy efficient these days. We're also seeing growth in unexpected places like Southeast Asia and parts of Africa, where local manufacturers are starting to incorporate vermiculite into their projects. As architects and builders continue prioritizing environmentally friendly options, vermiculite remains a go-to material for those wanting practical yet sustainable insulation solutions without breaking the bank.

Table of Contents

-

Thermal Performance of Vermiculite in High-Temperature Applications

- How Vermiculite's Mineral Structure Enhances Heat Resistance

- Comparing Vermiculite Board to Traditional Industrial Insulation Materials

- Non-Combustible Properties for Hazardous Environments

- Meeting Modern Building Codes and Safety Regulations

- Thermal Regulation for Reduced HVAC Demands

- Long-Term Cost Savings in Commercial Facilities

- Best Practices for Wall Cavities and Attic Applications

- Professional Installation vs. DIY Challenges

- Eco-Friendly Mineral Composition and Low Carbon Footprint

- Contribution to LEED and Green Building Certifications

- Understanding the Asbestos Connection in Historical Context

- Modern Safety Standards for Vermiculite Handling

- Future Trends in Vermiculite-Based Insulation Solutions