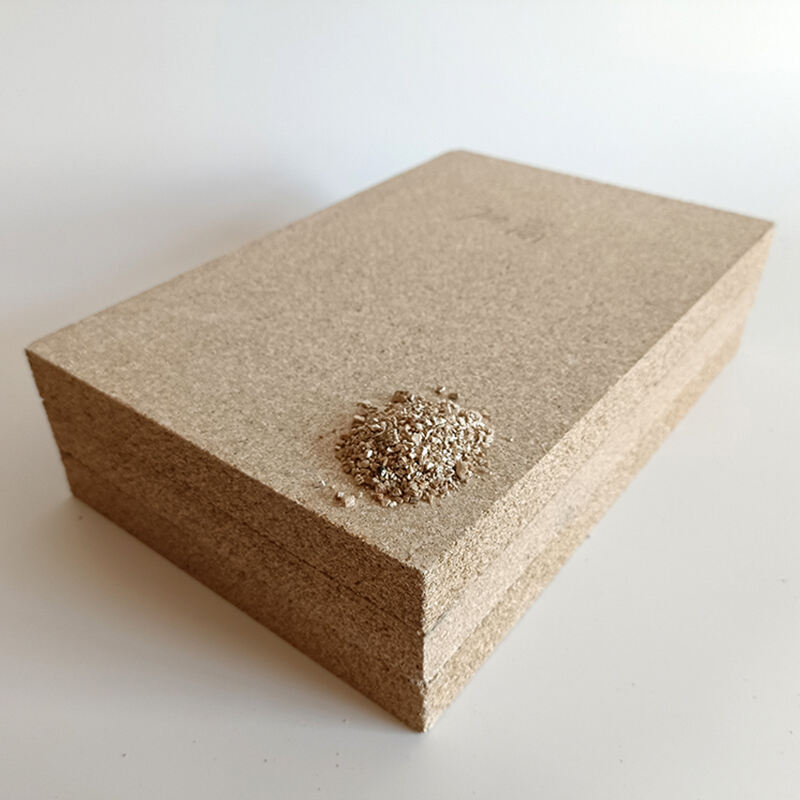

Hitaeðisvarmleiðandi eldssteinur, sem eru lykilkennsla í vöruúrvali Bitewater (Shenzhen) Technology Co., Ltd., eru hannaðir til að veita ósamanburðalega varmleiðslu í mjög erfðilegum iðnaðarsvæðum. Eldursteinar eru framkönnuðir úr hreinum hitaðstandandi efnum, eins og alúmínu og kísil, sem eru nákvæmlega valin fyrir frábæra hitastöðugleika og lágan hitaleiðni. Þessi samsetning af eiginleikum gerir hitaeðisvarmleiðandi eldssteinum kleift að verjast hitaflæði og viðhalda hámarkshitastigi innan ofna, steinbrennua og annarri hitaþungri tæki. Í stálframleiðslu eru þessir eldssteinar notaðir til að klæða blöndur og ofna, til að vernda byggingarhluti frá hitaáverkum og minka orkunotkun með því að lækka hitatap. Á sama hátt, í alúmíníum framleiðslu, tryggja þeir jafnaða hita dreifingu, sem bætir smeltieflæði og vöruháttur. Eldursteina er léttrar eðli sem auðveldar uppsetningu og minnkar byggingarþyngju, og þeir þar af leiðandi hentar bæði fyrir nýbyggingar og endurbætur. Þeirra ánægð í hitaskiptum tryggir lengstu notunartíma og koma í veg fyrir sprungur og skeljast af við fljóta hitabreytingu. Auk þess eru hitaeðisvarmleiðandi eldssteinar efnaóbrugðnir, sem verndar þá gegn rot og niðurbrots sem getur orðið af smeltum málum eða efnafræðilega virkum gasum. Áfram hafa framleiðsluaðferðir hjá Bitewater áhyggjulaust gæðastýringu og afköstum allra eldssteina, sem uppfyllir strangar kröfur iðnadarins. Eldursteinarnir eru fáanlegir í ýmsum tegundum og lögunum, sem gerir kleift að sérsníða þá að sérstökum notkunaraðilum. Með því að velja hitaeðisvarmleiðandi eldssteinu frá Bitewater geta iðnaðarverksefni náð miklum orkusparnaði, bætt afköstum og örvað öryggisstaðla. Langur notunartími og lág viðhaldsþörf gerir þá að kostnaðsæðilegri fjárfestni fyrir alla iðnaðarsviði sem þurfa á traustri hitaleiðslulausn.