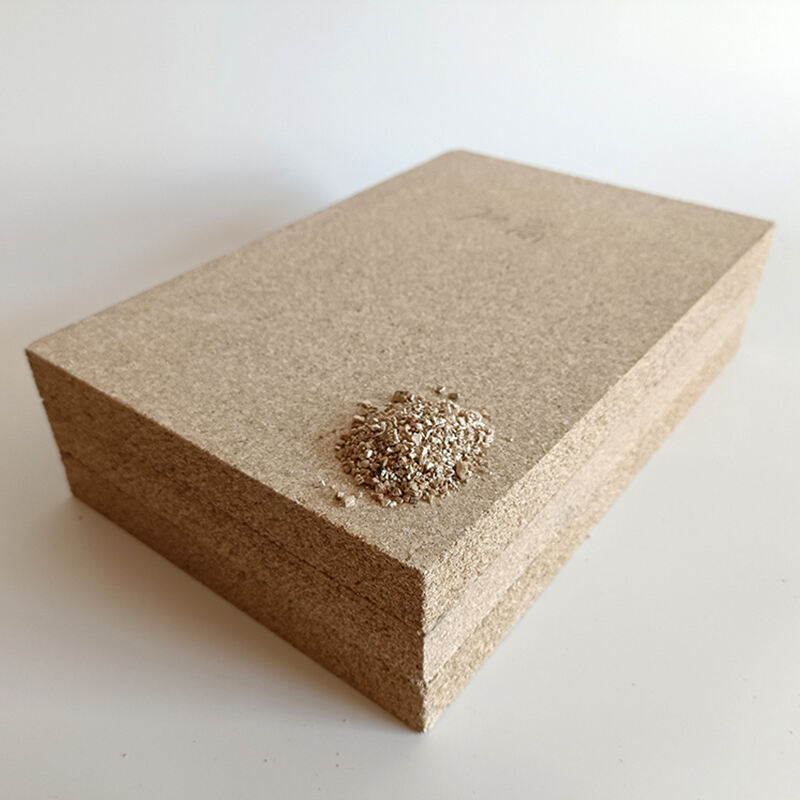

Firebrick for high-temperature applications is a specialty of Bitewater (Shenzhen) Technology Co., Ltd., a company renowned for its expertise in manufacturing insulation materials and fire protection vermiculite products. High-temperature environments, such as those found in steel ladles, aluminum melting cells, and industrial furnaces, demand firebricks that can withstand extreme thermal stress without compromising performance. Bitewater's firebricks are engineered using advanced refractory materials, including high-purity alumina and silica, which exhibit exceptional thermal stability and resistance to deformation. These firebricks are capable of withstanding temperatures exceeding 1,600掳C, maintaining their structural integrity and thermal insulation properties even under prolonged exposure to intense heat. Their low thermal conductivity minimizes heat loss, improving energy efficiency and reducing operational costs in industrial settings. Additionally, Bitewater's firebricks are resistant to thermal shock, preventing cracking or spalling due to rapid temperature fluctuations, which is crucial in applications where temperatures vary significantly. The firebricks' chemical inertness protects them from corrosion and degradation caused by molten metals or reactive gases, ensuring long-term reliability and performance. Bitewater's commitment to innovation and quality control guarantees that each firebrick meets stringent industry standards, providing customers with a reliable and cost-effective solution for their high-temperature application needs. Whether for new installations or retrofits, Bitewater's firebricks offer superior performance, durability, and safety, making them the preferred choice for industries requiring reliable thermal management solutions.