Thermal Performance of Vermiculite in High-Temperature Applications

How Vermiculite's Mineral Structure Enhances Heat Resistance

Vermiculite's unique mineral structure plays a pivotal role in its thermal insulation capabilities, especially in high-temperature settings. As a layered silicate mineral, vermiculite transforms significantly when subjected to heat by expanding, thereby creating air pockets within its structure. These air pockets function as excellent insulators, bolstering the material's ability to resist heat transfer. Studies have demonstrated that vermiculite outperforms other insulation materials like fiberglass or foam in extreme environments due to this characteristic expansion. This innate heat-resistant quality makes vermiculite indispensable in industries facing intense thermal challenges, such as aerospace and steel production. By selecting vermiculite, these industries can effectively manage thermal stress and enhance operational safety in high-temperature environments.

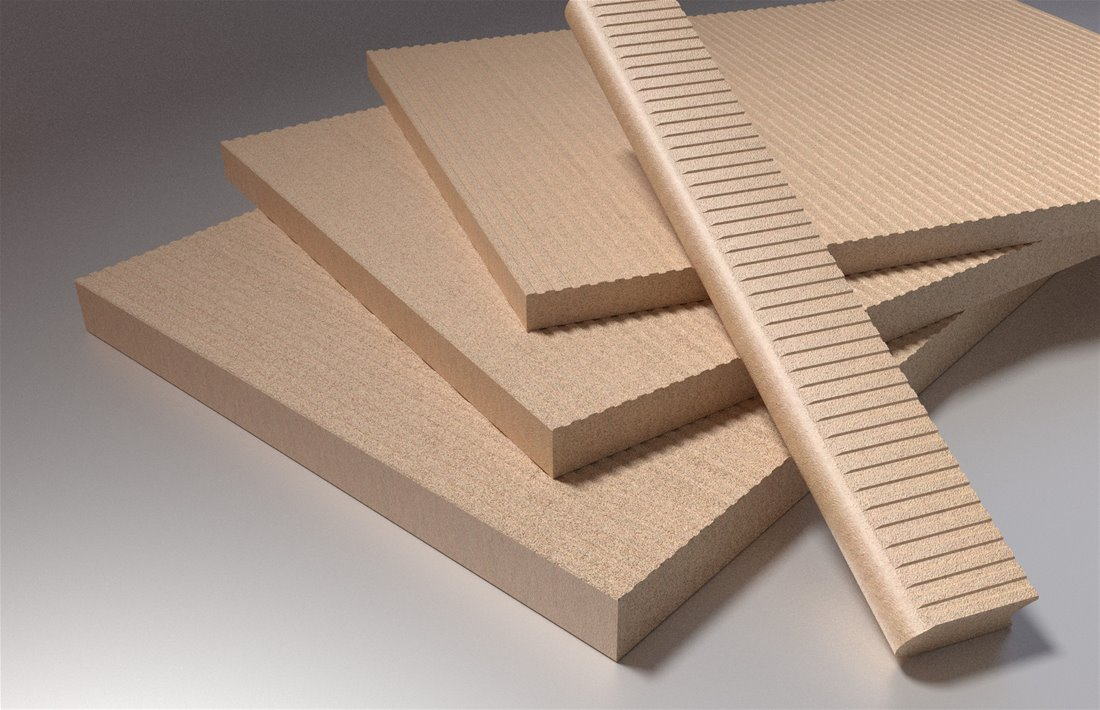

Comparing Vermiculite Board to Traditional Industrial Insulation Materials

Vermiculite boards present distinct advantages over traditional industrial insulation materials such as mineral wool and polystyrene. These boards are characterized by lower thermal conductivity, making them superior in heat retention. Additionally, vermiculite boards are lightweight, simplifying installation and reducing labor costs. In terms of durability, vermiculite exhibits remarkable resistance to moisture and mold, which validates its application in diverse high-heat scenarios based on industry standards. Environmentally, choosing vermiculite boards is a sustainable investment. Unlike synthetic materials, vermiculite's mineral composition is eco-friendly, contributing to reduced energy consumption and broader sustainability goals. These factors establish vermiculite boards as a prudent choice for both industrial applications seeking efficiency and environmental responsibility.## Fire Resistance and Safety Benefits Across Industries

Non-Combustible Properties for Hazardous Environments

Vermiculite's non-combustible nature offers crucial fire safety advantages in hazardous environments like chemical plants. This mineral does not ignite when exposed to flames, significantly lowering fire risks in areas prone to combustion. Statistics reveal that facilities using vermiculite insulation experience fewer fire incidents compared to those relying on conventional materials. Vermiculite retains structural integrity during fire conditions, outperforming other insulators that might degrade or emit toxic fumes. Recognized certifications affirm vermiculite's fire-resistance attributes, enhancing safety protocols in industries where fire hazards are a major concern. Therefore, opting for vermiculite insulation not only provides peace of mind but also ensures compliance with strict safety standards.

Meeting Modern Building Codes and Safety Regulations

Vermiculite insulation meets contemporary building codes for fire safety across various jurisdictions, making it ideal for projects needing strict regulatory compliance. The importance of adhering to these standards cannot be overstated, as choosing subpar insulation can lead to severe safety issues, potentially risking lives and property. Government guidelines explicitly emphasize the use of materials like vermiculite that demonstrate excellent fire safety measures. Projects integrating vermiculite, such as modern industrial facilities, have successfully aligned with rigorous safety regulations, showcasing vermiculite's adaptability and reliability. Thus, employing vermiculite ensures both environmental responsibility and adherence to essential safety protocols, underscoring its value in contemporary construction practices.## Energy Efficiency Advantages in Industrial and Residential Settings

Thermal Regulation for Reduced HVAC Demands

Vermiculite insulation plays a crucial role in stabilizing indoor temperatures, significantly reducing the need for HVAC systems. Its high-temperature insulation properties minimize heat transfer, thereby conserving energy by reducing heating and cooling demands in various settings. For instance, case studies have shown that buildings employing vermiculite have experienced notable decreases in HVAC energy consumption. This capability is vital not only for energy efficiency but also for industrial and residential settings, where maintaining stable temperatures can translate into substantial energy conservation. Statistics reveal that compared to traditional insulation materials, vermiculite can lead to energy savings of up to 30%, showcasing its potential as a superior choice in energy efficiency efforts.

Long-Term Cost Savings in Commercial Facilities

Implementing vermiculite insulation in commercial facilities can yield significant long-term cost savings. While the initial investment may be higher, the reduction in energy bills and maintenance costs over time makes vermiculite a financially sound choice. Several studies and reports predict future savings by analyzing current energy prices and emerging climate control technologies. Real-world examples abound, with businesses reporting substantial decreases in overhead costs after switching to vermiculite insulation. Not only does it offer protection against fluctuating energy prices, but vermiculite's durability also ensures reduced maintenance expenses, further enhancing its cost-effectiveness in commercial applications.## Installation Techniques for Optimal Insulation Performance

Best Practices for Wall Cavities and Attic Applications

Proper installation of vermiculite in wall cavities and attics is crucial for maximizing its thermal properties. Vermiculite is renowned for its efficiency as a high-temperature insulation product, often preferred over other industrial insulation materials due to its lightweight and fire-resistant nature. For wall cavities, it is recommended to fill all gaps completely to avoid cold spots. When working with attics, ensure that vermiculite covers the entire area uniformly to prevent any thermal bridges. These areas can pose unique challenges, such as uneven surfaces or difficult access. As a solution, vermiculite excels because it can be poured into spaces and spread evenly, making it ideal for any shape or form. Common mistakes include improper sealing and uneven distribution. To ensure optimal effectiveness, it is important to follow detailed instructions or diagrams, often available through vermiculite board manufacturers and suppliers.

Professional Installation vs. DIY Challenges

Choosing between professional installation and a DIY approach can significantly affect the effectiveness of vermiculite insulation. Professional installers are equipped with the expertise necessary to navigate potential pitfalls and achieve optimal results in insulation applications. They ensure complete coverage and correct installation techniques, which are essential for maintaining the insulation's integrity and performance over time. Alternatively, DIY projects, while cost-effective, can lead to reduced effectiveness if not executed correctly. Pitfalls such as uneven distribution or improper sealing can compromise the insulation's efficiency. It’s important to weigh the benefits of professional services against the challenges of DIY installations. Consult reliable DIY guides and thoroughly research methods if undertaking the task personally. For those deciding on professional services, resources for finding qualified professionals are readily available, ensuring the insulation of vermiculite meets the highest standards.## Environmental Sustainability of Vermiculite Insulation

Eco-Friendly Mineral Composition and Low Carbon Footprint

Vermiculite is a naturally occurring mineral, renowned for its eco-friendly attributes and low carbon footprint in insulation applications. Its journey begins with mining, where minimal energy is consumed compared to synthetic insulation materials, making its lifecycle substantially sustainable. Moreover, vermiculite contributes significantly to reducing greenhouse gas emissions in buildings throughout their lifespan, aligning with sustainable construction practices. Acknowledged by various environmental certifications, vermiculite is often chosen for its commitment to minimizing environmental impact, providing a viable alternative to conventional insulation.

Contribution to LEED and Green Building Certifications

Vermiculite insulation plays a pivotal role in achieving LEED certification and other green building standards, further promoting its use in sustainable construction. As the demand for environmentally conscious building materials grows, vermiculite stands out due to its ability to contribute substantial points in these certifications. Case studies of LEED-certified projects demonstrate the effective integration of vermiculite, paving the way for more sustainable urban development. Market trends reveal that there is a rising demand for green materials in construction, supported by industry data showing increased investment in eco-friendly resources.## Safety Protocols and Regulatory Compliance

Understanding the Asbestos Connection in Historical Context

Vermiculite insulation has a complex history, notably marked by concerns regarding asbestos contamination. Historically, some vermiculite products contained asbestos, leading to health risks. However, modern regulatory compliance has effectively minimized these concerns. The Environmental Protection Agency (EPA) has conducted studies ensuring that current vermiculite insulation products are safe and asbestos-free. These products now adhere to stringent standards, making them reliable for use in various applications. It is crucial to use certified vermiculite products, which are confirmed to be free from asbestos, as they guarantee compliance with safety protocols and ensure protective measures for users.

Modern Safety Standards for Vermiculite Handling

Handling and installing vermiculite insulation require adherence to modern safety standards to ensure protection for both workers and end-users. Current guidelines dictate best practices for safe handling, emphasizing the importance of proper installation in residential and industrial contexts. Training and certification programs are available for professionals, ensuring they are equipped with the necessary skills and knowledge to manage vermiculite safely. These resources provide updated safety information and awareness of regulatory changes concerning vermiculite, ensuring ongoing compliance and safety in its application.

Future Trends in Vermiculite-Based Insulation Solutions

Innovations in High-Temperature Insulation Products

Emerging technologies are continually revolutionizing the production of vermiculite for high-temperature applications. These advancements focus on enhancing the material's heat resistance and expanding its versatility in harsh environments. High-temperature insulation products are seeing a shift towards hybrid solutions, combining vermiculite with other high-performance materials to optimize insulation efficiency. Industry leaders speculate on future advancements in vermiculite insulation technologies, predicting improvements in energy efficiency and a broader range of applications. This innovation is critical as it promises not only to transform insulation capabilities but also to offer more sustainable options to meet evolving industry standards.

Projected Growth in Construction and Manufacturing Sectors

Market trends indicate a promising growth trajectory for vermiculite in both construction and manufacturing sectors. As demand for high-temperature insulation products increases, vermiculite stands out due to its affordability and effective thermal properties, which align with sustainability goals. Statistics demonstrate a substantial expansion in these sectors, predicting further adoption of vermiculite insulation driven by energy efficiency imperatives. Additionally, regions previously unexplored are emerging as new markets, contributing significantly to the global demand. The importance of sustainable building practices sparks interest in vermiculite, highlighting its role as a key player in the future of eco-friendly construction solutions.