Key Factors in Fire Board Selection for High-Temperature Applications

Thermal Conductivity & Fire Resistance Ratings

Thermal conductivity matters a lot when picking out fire boards for those really hot environments. Basically, it tells us how good a material is at stopping heat from moving through it, which keeps structures intact even when exposed to flames. Materials with lower thermal conductivity don't let much heat pass through them, so they offer better protection not just for buildings but also for people inside. Most professionals rely on fire resistance ratings like ASTM E84 or EN 13501-1 to pick the right boards. These ratings come from thorough tests that look at things like how fast flames spread across surfaces and how much smoke gets produced. Firefighters and building inspectors know this stuff works because in actual fires, boards with higher ratings tend to cut down damage by around half compared to lower rated alternatives. That makes all the difference in keeping buildings safe and reducing losses after incidents.

Material Durability Under Extreme Heat

How well fire boards hold up matters a lot when assessing their performance in tough situations. Things like how they handle sudden temperature changes and extended periods of intense heat really impact how long they last. From what we know about materials, good quality fire boards should be able to take repeated heating and cooling cycles plus stay strong even after being exposed to very high temperatures for weeks on end. This means they provide dependable protection against fires over many years. On the flip side, going cheap on materials often leads to problems down the road. Boards made with poor quality stuff tend to break down faster, which means expensive fixes later on and creates real safety hazards too. Think about factories or warehouses where equipment needs to work reliably day after day without fail. Spending money upfront on solid, lasting fire boards isn't just about protecting buildings though it's actually smart business practice that keeps operations running smoothly while everyone stays safe.

Compatibility with Structural Steel Protection

Getting fire boards to work well with structural steel matters a lot when it comes to avoiding collapse during fires. Fire protection materials need to match how steel behaves under heat conditions. Steel expands when heated, so fire boards should be able to handle similar expansion rates without cracking or peeling off. The real test happens when engineers check how these materials respond together under extreme temperatures. Some buildings have failed catastrophically because the wrong type of fire board was used on certain steel components. Take the warehouse fire in Chicago last year as an example – improper material pairing caused critical structural weaknesses that accelerated the collapse. Building codes now require extensive compatibility testing before installation. When architects get this right, buildings stand stronger against fire threats, protecting both property and lives in the long run.

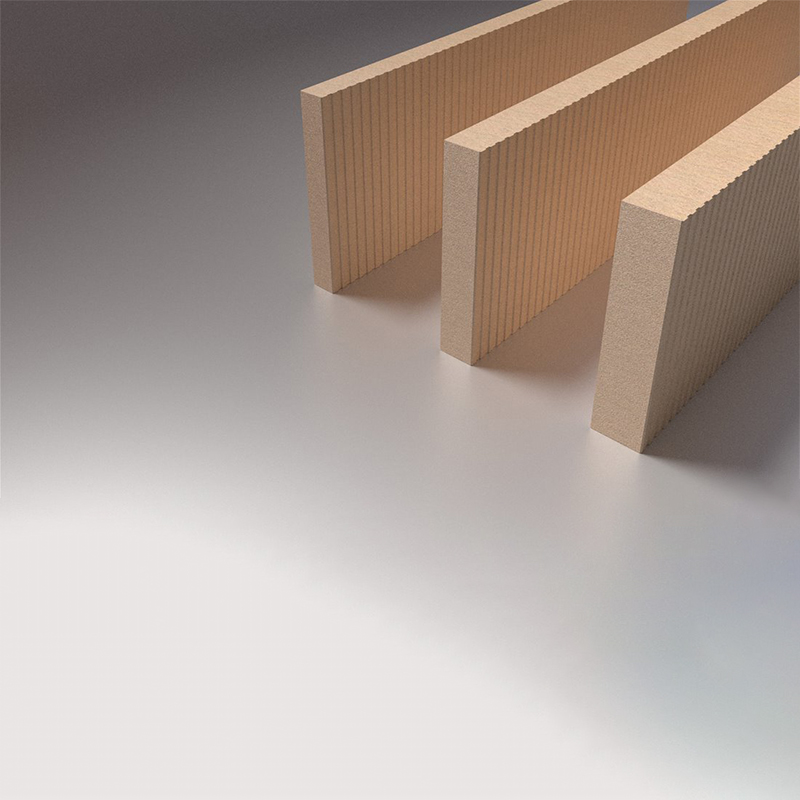

Advantages of Vermiculite in Industrial Settings

Vermiculite firebrick insulation has some pretty impressive thermal characteristics which is why it works so well in industrial applications. The material can withstand extremely high temperatures thanks to its melting point around 1300°C while still keeping heat from transferring too quickly because of its low conductivity rate. That's why many factories and manufacturing plants rely on vermiculite when they need something that won't fall apart under intense heat conditions. Compared to traditional mineral wool alternatives, vermiculite weighs about half as much and comes in blocks that are much easier for workers to lift and position during installation. According to industry veteran Mark Allison who's worked with these materials for over 25 years, "What sets vermiculite apart isn't just its ability to resist flames but how consistently it performs day after day in those brutal industrial furnaces without losing effectiveness." This reliability makes all the difference when safety standards are at stake.

Mineral Wool's Moisture Resistance Properties

Mineral wool boards really stand out when it comes to resisting moisture, something that matters a lot for stopping mold from growing and reducing fire dangers in damp places. Tests have shown these boards take in very little water, which cuts down on all sorts of problems caused by excess moisture. Some actual lab tests measured absorption at just around 0.2%, making them pretty impressive compared to other options. When buildings need protection against humidity, mineral wool becomes essential because it helps keep structures intact longer while also improving fire safety. Regular construction materials tend to break down faster when exposed to constant moisture, so this makes a big difference over time.

LSI Integration: Board Manufacturers' Material Innovations

Manufacturers making vermiculite boards are constantly coming up with new stuff that changes how we think about fire protection. Lately there's been a big push toward green materials and composite boards that do double duty for both insulation and stopping fires. The whole insulation business is moving toward sustainability right now, which means building codes are getting updated all the time. Some experts in the field say this wave of innovation could really shake things up when it comes to fire safety rules down the road. After all, buildings today need materials that work well together while meeting stricter environmental standards, so architects and builders have no choice but to adapt fast.

Certification Requirements for High-Performance Fire Boards

EN 13501-1 & ASTM E136 Compliance

Fire board certification relies heavily on two main standards: EN 13501-1 and ASTM E136. These standards make sure that building materials actually stand up to fire safety tests before they get approved for use. EN 13501-1 works mainly across Europe where it classifies how different construction products behave when exposed to flames. Over in North America, ASTM E136 does something similar but focuses specifically on whether materials will burn at all. Most manufacturers stick closely to these standards because getting certified makes all the difference when selling products. Companies that skip compliance often find themselves struggling hard in the marketplace. One industry study showed that firms caught with non-compliant fire boards lost not just customer confidence but also faced serious fines and lawsuits. That's why proper certification remains so important for anyone working with building materials today.

Third-Party Testing for Fire Safety Assurance

Independent testing is really important when it comes to fire board quality and reliability. The thing is, these outside groups actually check if what manufacturers say about their products' fire safety holds up under real conditions. That helps build trust across the whole industry. Take UL and Intertek for instance – they're two big names in this space known for running tough tests on materials. We've seen how this kind of third party validation makes a difference in practice too. Fire boards that pass rigorous testing tend to last longer and perform better in actual installations. Clients naturally feel more confident about specifying products that have been properly tested, which ultimately leads to safer buildings and fewer callbacks down the road.

Global Standards for Structural Fireproofing

The way countries set their structural fireproofing standards really affects which fire boards get picked around the world. When companies stick to these rules, they not only keep people safe but also make sure their products work in different markets. Groups like ISO have been trying to bring some consistency across borders so businesses don't face so many roadblocks when trading internationally. Still there are plenty of differences between regions that cause problems for manufacturers. Take Europe versus America for example. A board approved in Germany might need some changes before it can be sold here in the US. That's why anyone working with fireproofing materials needs to know what kind of regulations apply where they operate.

Installation Strategies for Optimal Fire Protection

Weather-Resistant Installation Techniques

Getting fire boards installed right across different climates requires using weather resistant approaches. Materials matter a lot since they need to handle all sorts of temperature changes and humidity without falling apart. Sealing things properly stops water getting in, something that really matters because dampness just eats away at the boards over time. What happens at the joints between panels is critical too for keeping fires contained. We saw this work well in Estonia where factories kept their fire protection intact even when dealing with those brutal Nordic winters and springs thanks to careful attention paid during installation. The folks there basically followed these steps religiously and avoided major issues down the road.

Space-Saving Frameless System Advantages

Frameless systems bring real advantages when it comes to installation work because they make better use of available space while looking much nicer too. Without all those bulky frames that traditional setups require, designers can create really clean, modern looks. Beyond just looking good, these systems actually perform well in terms of insulation and fire resistance so safety remains intact even when going for something stylish. We're seeing this become increasingly popular in city apartments and other urban housing developments where every square foot counts. People want their buildings to be practical but still visually appealing, and frameless options hit that sweet spot between functionality and attractive design.

Maintaining Fire Integrity in Complex Structures

When architects get creative with their designs, fire safety becomes a real headache. Still, there are ways to tackle these problems head on. For buildings with complicated layouts, fireproofing isn't just about slapping on materials anymore. The team needs to constantly inspect different parts of the structure too. Take the recent work at the Guggenheim Museum for instance. They managed to install special fire resistant coatings without messing up those iconic curves and lines that make the place famous. Safety stayed intact though. Another important piece of the puzzle? Keeping the workers trained properly. Installation crews need regular updates on new methods because every building throws up different challenges. Some might require traditional approaches while others demand completely new thinking.

Evaluating Long-Term Performance in Harsh Environments

Resistance to Thermal Cycling & Moisture

When fire board materials go through constant heating and cooling cycles, their durability takes a real hit over time. In places where temperatures swing wildly back and forth all day long, these materials expand when hot then contract when cold, creating tiny cracks that eventually lead to bigger problems down the road. Some studies have actually shown that certain materials handle this better than others. Vermiculite based boards stand out for their ability to take repeated temperature changes without falling apart. Take a look at what happens in steel mills or aluminum foundries where insulation must survive extreme heat fluctuations daily. The manufacturers there aren't just guessing about what works best. They've developed special binding techniques and carefully mixed raw materials to create products that resist both thermal stress and water damage. These improvements mean equipment lasts longer even in the toughest operating environments.

Acoustic & Thermal Bridging Considerations

Fire board evaluation needs to include acoustic performance because sound control plays a big role in building safety too. Good insulation does double duty by stopping fires from spreading and cutting down on noise levels, something that matters a lot in both homes and office spaces. The problem comes when thermal bridging happens. Heat finds ways around fireproof barriers, creating dangerous situations. Contractors often deal with this by making sure all those tricky intersection points are properly insulated and applying specialized sealants at critical joints. Different countries have their own rules about what counts as acceptable acoustic and thermal performance for fire boards. These regulations aren't just bureaucratic hurdles they actually help ensure buildings stay safe during emergencies while still keeping unwanted noise at bay between apartments or workspaces.

Case Study: Tunnel Applications with Firemaster T-Board

Firemaster T-Board has earned praise for how well it resists flames, which makes it great for tunnels where fire safety matters most. We recently installed these boards in one of the big city tunnels, and they performed really well under some pretty intense conditions that only happen in those underground spaces. The engineers who worked on the project were impressed too. They saw firsthand how the material held up structurally even when exposed to heat during testing. What stood out was just how good the insulation properties are at stopping heat from moving through the material. That kind of performance makes all the difference in infrastructure projects where fire protection needs to be rock solid. Seeing this product work so well in actual tunnels shows why picking the right materials matters so much when dealing with tough environmental situations.