Superior Thermal Performance of Vermiculite Insulation

Heat Resistance Capabilities for Extreme Environments

Vermiculite insulation stands out because it can handle really high temperatures, around 1000 degrees Celsius before breaking down. That kind of durability explains why many factories and plants rely on it for areas near furnaces or wherever things get super hot. Regular insulation just wouldn't cut it there. What makes vermiculite special is how poorly it conducts heat compared to most other materials. This means it keeps heat inside better, which actually saves money on energy bills over time. When looking at long term projects involving constant exposure to intense heat, vermiculite comes out ahead of standard options when it comes to both keeping things running smoothly and staying safe. Many boiler rooms, kilns, and even some automotive manufacturing facilities depend on this material specifically for these reasons.

Energy Efficiency in Industrial Temperature Regulation

Switching to vermiculite insulation typically cuts down on energy use quite substantially, sometimes reaching around 40% in places where temperature matters a lot, leading to big money savings over time. The improved efficiency affects what companies spend on running things day to day while helping keep temperatures just right during production processes. Getting this control right makes all the difference when it comes to making better products and cutting down on wasted materials. A bunch of factories have actually seen their energy bills go down after making the switch to vermiculite. What these experiences show is that vermiculite works really well as insulation for industrial settings. For manufacturers looking to cut back on power consumption, going with vermiculite options could be worth considering if they want to run things more efficiently and stay green at the same time.

Long-Term Stability in Thermal Applications

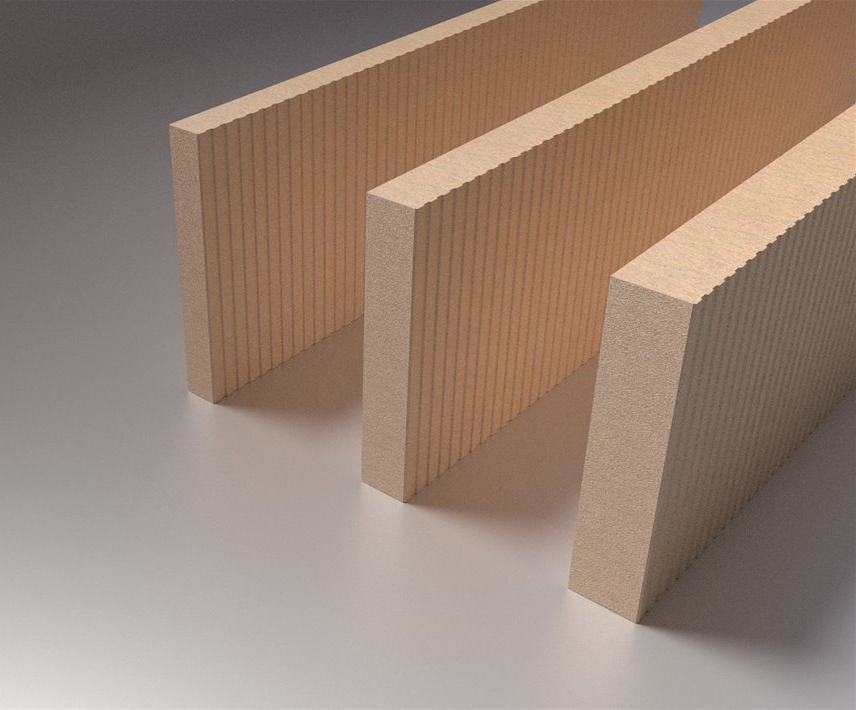

Vermiculite insulation holds up pretty well dimensionally speaking, which means it keeps performing consistently even when temperatures swing around. Most other insulations tend to sag or break down over time, but not so much with vermiculite. It stays put and works reliably right through its whole life cycle. Industry studies back this up too showing very little wear and tear after many years in service. That's why folks keep turning to vermiculite when they need something that won't let them down in hot environments. Manufacturers who produce vermiculite boards often point out how these materials handle extreme heat situations without losing their effectiveness. From industrial furnaces to residential fireplaces, vermiculite stands up where others might buckle, making it a solid investment for anyone looking at long term thermal protection solutions.

Inherent Fire Resistance Properties

What makes vermiculite stand out as a fire resistant material lies in its basic composition. The stuff simply won't catch fire under normal conditions, which gives buildings a real edge when fires break out unexpectedly. When things get hot, vermiculite stays put without releasing harmful gases into the air, something that matters a lot during emergencies where smoke inhalation is often deadly. Tests show buildings using vermiculite insulation actually hold up better against flames than many standard construction materials do. For architects and builders aiming to meet tough fire codes while keeping occupants safe, this mineral offers both protection and peace of mind without breaking the bank on expensive alternatives.

Meeting Global Fire Safety Standards

When it comes to fire safety, vermiculite insulation really shines because it meets and sometimes even beats important international standards like ASTM E84 and EN13501. For companies looking to keep their buildings up to code across different regions, this kind of performance makes life much easier when dealing with all sorts of safety requirements. The fact that vermiculite has these official certifications speaks volumes about how trustworthy it actually is as a construction material. This becomes especially important in places like hospitals or schools where following strict safety guidelines isn't just recommended but absolutely necessary for everyone's protection.

Protection for High-Risk Industrial Facilities

Vermiculite insulation is really important for places where fires are a big concern, like refineries and power plants. These kinds of facilities need good fire protection not just to keep workers safe but also because insurers demand it as part of their coverage terms. Studies have shown that buildings with vermiculite tend to have fewer fire incidents than ones using different insulating materials. That makes sense when we think about how well vermiculite resists heat and doesn't contribute to spreading flames. For companies operating in these dangerous environments, investing in proper vermiculite insulation isn't optional it's essential for both employee safety and business continuity.

Construction: Walls, Roofs, and Flooring Systems

In construction circles, vermiculite boards have become pretty much indispensable because they work so well at insulating spaces and stopping fires from spreading. Builders install them across all sorts of properties these days, whether it's homes or office complexes, since they really boost thermal performance and make environments more pleasant for people inside. What stands out is how light these boards actually are compared to other materials on the market today. The lighter weight means contractors can get the job done faster without needing extra manpower, which cuts down on those pesky labor expenses that always seem to creep up during construction projects. Plus there's something else going for them too – these boards help cut down on unwanted sounds traveling through walls and ceilings. We've seen firsthand how much difference good acoustic insulation makes in apartments where neighbors complain about every little sound. Given all these advantages covering both temperature control and sound management, most manufacturers who produce vermiculite boards will tell anyone listening that their product remains one of the top picks when it comes to building insulation solutions.

Industrial Applications: Furnaces and Pipe Insulation

Vermiculite boards play a key role in industrial pipe insulation, helping keep steam and various fluids at just the right temperature during transport through factory systems. These boards find another important application inside furnaces too, where they actually help save energy by making sure heat gets distributed properly throughout the system. Many manufacturing plants across different sectors have noticed better heat retention and lower utility bills after switching to vermiculite insulation materials. Some steel mills and chemical processing facilities specifically mention up to 15% savings on annual heating costs since implementing this type of insulation. When looking at actual plant operations, it becomes clear why so many maintenance managers prefer vermiculite boards for both new installations and retrofitting older systems.

Agricultural Uses: Soil Enhancement and Moisture Control

In farming circles, vermiculite boards have become pretty important over time because they help with two big issues: getting air into the soil and keeping water where plants can actually use it. When soil stays aerated properly and holds moisture better, plants generally grow stronger and produce more food without needing constant watering. Farmers love this since it cuts down on their water bills while still giving good results from their fields. What makes vermiculite special is how its structure works kind of like a sponge that absorbs excess moisture when there's too much rain but releases it back slowly during dry spells. Studies looking at different farms show noticeable improvements in crop yields after adding vermiculite to poor quality soils, especially for things like tomatoes and peppers that really struggle with inconsistent watering. So beyond just being good for the dirt itself, using vermiculite actually helps farmers work smarter rather than harder in their day to day operations.

Natural Mineral Composition and Recyclability

As a naturally occurring mineral that doesn't contain toxins, vermiculite has become a favorite among businesses focused on green practices. The fact that it poses no environmental risks means companies can meet even the toughest sustainability requirements without headaches. What really stands out about vermiculite insulation though is how easy it is to recycle. When builders reuse this material instead of sending it to landfills, they cut down on waste while saving precious natural resources at the same time. This kind of thinking supports what we call a circular economy where nothing goes to waste. Construction firms across the country are starting to notice something interesting too. Projects using materials like vermiculite tend to score much better on sustainability reports, which matters a lot when trying to get LEED certification or simply appeal to environmentally aware customers.

Reducing Carbon Footprint Through Energy Conservation

Vermiculite insulation actually saves quite a bit of energy over time, which means less greenhouse gases going into the atmosphere. Many manufacturers who switch to this type of insulation start seeing real benefits pretty quickly. Some even qualify for tax breaks or special programs from local governments, making green initiatives pay off financially as well as environmentally. Studies show that buildings with good insulation cut down on their carbon output significantly. Materials such as vermiculite play a big role here because they help companies reduce waste while still maintaining comfort levels inside facilities. This makes sense both for planet protection and bottom line considerations when looking at long term costs.

Compatibility with Green Building Certifications

Vermiculite insulation ticks off boxes for several green building certifications including LEED, which makes it pretty much ideal for projects that want to go green. When builders include these kinds of sustainable materials, they aren't just checking off certification requirements. They're actually improving how attractive their projects look to potential buyers who care about going green. Industry experts have pointed out time and again that vermiculite really does help reach those sustainability goals in construction work. For companies serious about being part of the eco-friendly building movement, this material has become something of a secret weapon in their toolkit for getting established in the growing green construction market.

Advanced Processing Eliminating Asbestos Risks

Modern manufacturing facilities have developed sophisticated methods to get rid of asbestos contamination when working with vermiculite. We all know asbestos poses serious health risks, so manufacturers go through extra steps to make sure their vermiculite products don't contain any harmful fibers. These safety measures follow government standards set by agencies like OSHA and EPA, which gives both regular people and industrial users peace of mind about what they're buying. Major health groups including the CDC consistently stress how important it is to produce materials free from asbestos, which actually makes sense when looking at the long term benefits for public health and business reputation.

Certification Processes by Leading Manufacturers

Top producers of vermiculite boards go through extensive testing and get certified so their products actually meet those claimed standards. The whole production process gets checked at multiple points - from raw material inspection right down to final packaging. Companies run these quality control tests not just because they have to, but because it makes business sense too. When boards carry certifications from bodies like ASTM or ISO, customers know they're getting something safe and effective for their money. These marks on the packaging aren't just there for show either; they represent real work behind the scenes to ensure what ends up in construction sites performs reliably year after year.

Global Supply Chain Reliability from Trusted Suppliers

Having reliable supply chains matters a lot when it comes to keeping vermiculite insulation products consistently available while maintaining quality standards. When manufacturers partner with trusted suppliers, they tend to get a steady flow of good quality vermiculite that meets what the market needs. Research from industry reports indicates businesses that maintain strong relationships with their suppliers face fewer interruptions in production and generally run smoother operations overall. This makes sense because nobody wants delays or subpar materials showing up at critical moments. A dependable supply network isn't just nice to have it's actually essential for anyone serious about producing quality insulation materials consistently over time.

Table of Contents

-

Superior Thermal Performance of Vermiculite Insulation

- Heat Resistance Capabilities for Extreme Environments

- Energy Efficiency in Industrial Temperature Regulation

- Long-Term Stability in Thermal Applications

- Inherent Fire Resistance Properties

- Meeting Global Fire Safety Standards

- Protection for High-Risk Industrial Facilities

- Construction: Walls, Roofs, and Flooring Systems

- Industrial Applications: Furnaces and Pipe Insulation

- Agricultural Uses: Soil Enhancement and Moisture Control

- Natural Mineral Composition and Recyclability

- Reducing Carbon Footprint Through Energy Conservation

- Compatibility with Green Building Certifications

- Advanced Processing Eliminating Asbestos Risks

- Certification Processes by Leading Manufacturers

- Global Supply Chain Reliability from Trusted Suppliers