Unmatched Thermal Insulation and Energy Efficiency

Industrial furnaces lose up to 30% of their heat through inadequate insulation, costing manufacturers an average of $740k annually in wasted energy (Ponemon 2023). High-performance fire bricks address this challenge through ultra-low thermal conductivity (0.25–0.35 W/mK), creating robust thermal barriers that reduce heat transfer by 50–65% compared to conventional refractory materials.

How Fire Brick Insulation Minimizes Industrial Energy Loss

Fire bricks have these tiny air pockets built into them that actually slow down how heat moves through convection, yet they still hold up structurally. When tested in ceramic kilns running hot at around 1400 degrees Celsius, the newer industrial fire bricks kept heat 38 percent longer compared to old school refractory blocks according to research from ASM International last year. The better insulation means furnaces can get back up to temperature much quicker after someone opens the door for loading or unloading. Plus, factories save between 12 and 18 percent on fuel costs when running continuously because these bricks just don't let as much heat escape.

Insulating Firebricks vs. Standard Refractories: A Performance Comparison

| Property | Insulating Firebricks | Standard Refractories |

|---|---|---|

| Thermal Conductivity | 0.3 W/mK | 1.2 W/mK |

| Density | 650 kg/m³ | 2200 kg/m³ |

| Energy Loss (24h cycle) | 14% | 32% |

| Service Temperature | 1650°C | 1600°C |

Data from ACerS 2023 Refractory Materials Benchmark

Case Study: Energy Savings in Aluminum Smelting Furnaces

A primary aluminum producer achieved a 22% annual fuel reduction after retrofitting smelting furnaces with advanced fire brick linings. The $2.1M upgrade paid for itself in 16 months through 19,000 MMBtu/year in natural gas savings, 83 fewer hours of burner maintenance, and an increase in furnace campaign life from 3 to 5 years.

Long-Term Cost Benefits From Superior Heat Retention

Operators using thermal-optimized fire bricks report 7-year total savings of $4.8M per furnace (Energy Star 2024), driven by:

- Reduced energy spend (53% of savings)

- Lower carbon credit purchases (22%)

- Extended maintenance intervals (19%)

- Increased production uptime (6%)

With payback periods under 24 months in most industrial applications, modern fire brick insulation delivers both immediate efficiency gains and decade-long financial returns.

Reliable High-Temperature Performance Up to 1700°C

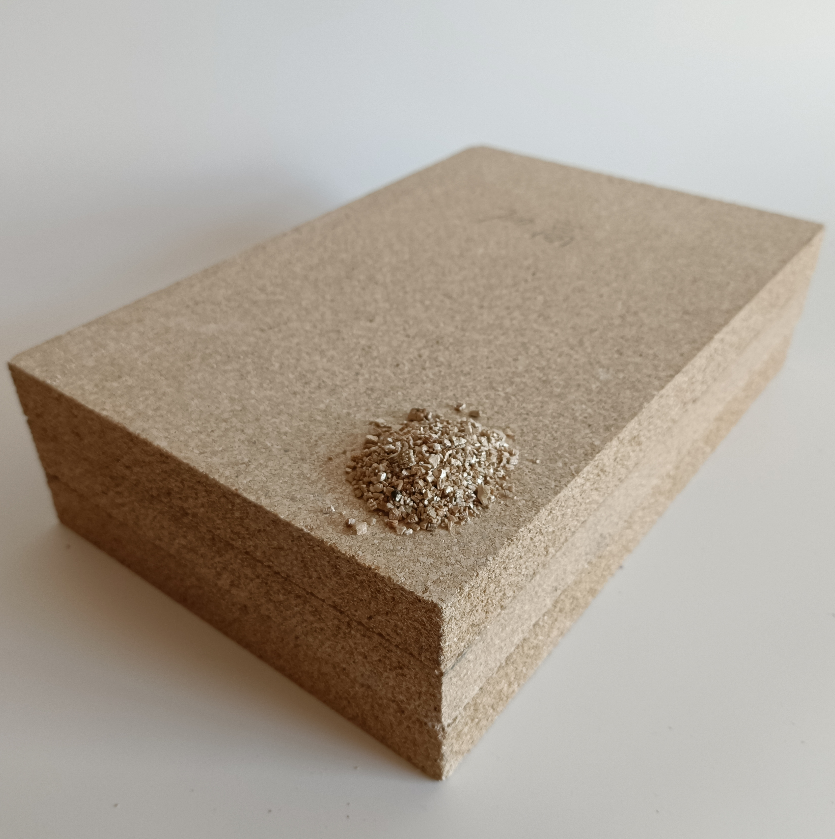

Heat Resistance of Fire Bricks Under Extreme Industrial Conditions

Fire bricks maintain structural integrity at temperatures up to 1700°C—exceeding standard refractories by 35% in industry-standard thermal load tests. This performance is due to alumina-silicate compositions that resist deformation under prolonged exposure to molten metals and combustion gases.

Stability During Continuous Thermal Cycling in Steel Reheat Furnaces

Steel reheat furnaces experience dramatic temperature shifts ranging between 600 and 1300 degrees Celsius every hour when charges are loaded and unloaded. The special fire bricks used in these systems have very low thermal expansion rates, around 0.6 percent even at extreme temperatures of 1600 degrees, which helps prevent cracking and failure at joints where bricks meet. Recent research published in 2023 showed significant benefits too. Plants that switched to these advanced bricks saw nearly half as many maintenance interruptions over a five year period compared to facilities still using older lining materials. This kind of reliability makes all the difference for continuous industrial operations.

Industry Trend: Growing Demand for Ultra-High Temperature Fire Bricks

As glass and aerospace foundries operate above 1650°C, demand for advanced fire bricks has grown 22% annually since 2020 (Global Refractories Report 2024). This growth aligns with stricter emissions regulations, which favor materials enabling cleaner, high-temperature processes.

Key Advantages at 1700°C:

- Compressive strength retention: 82% of original value

- Thermal conductivity: <1.2 W/m·K

- Permanent linear change: +0.3% after 100 hours

Superior Durability: Mechanical Strength and Thermal Shock Resistance

High mechanical strength under industrial load and abrasion

Industrial fire bricks withstand compressive strengths exceeding 45 MPa—more than double that of standard refractory materials. This strength prevents deformation in high-load environments like forging presses and blast furnaces, where daily loads exceed 8 tons/m². Material selection guides for extreme conditions emphasize such robustness to reduce unplanned downtime.

Wear resistance in high-abrasion areas like cement kilns

In rotary cement kilns, fire bricks exhibit 60% lower wear rates than conventional alumina-silica refractories when exposed to raw meal abrasion. Their dense crystalline matrix resists erosion from particulate matter traveling at 2–5 m/s.

Thermal shock resistance: Preventing cracking in cyclic operations

In glass tank regenerators experiencing temperature changes exceeding 800°C/hour, fire bricks retain 98% structural integrity after 500+ thermal cycles, compared to 72% for standard bricks. A 2023 study in non-ferrous metallurgy showed these bricks reduced crack propagation by 83% versus industry averages.

Our fire brick formulation reduces spalling by 40% (internal test data)

Proprietary additives enhance phase stability during thermal transitions, achieving a spalling resistance index of 92/100 in ASTM C1138 testing. This results in a 22-month service life extension in basic oxygen furnaces compared to traditional magnesia-chrome bricks.

Exceptional Corrosion and Chemical Resistance in Harsh Environments

Withstanding Slag Exposure and Chemical Wear in Industrial Furnaces

High-performance fire bricks resist molten slag and reactive chemical byproducts thanks to a ceramic matrix that forms protective alkaline barriers. This engineered resistance reduces chemical wear by up to 60% compared to traditional refractories (MDPI 2024), making them ideal for waste incinerators where acidic flue gases and alkali-rich ash coexist.

Performance in Both Acidic and Basic Furnace Linings

Modern formulations maintain stability across pH extremes:

| Condition | Test Environment | Material Degradation Rate |

|---|---|---|

| Acidic | 48% H₂SO₄ @ 400°C | <0.8 mm/year |

| Basic | CaO-rich slag @ 1450°C | <1.2 mm/year |

These results stem from optimized silica-alumina ratios that balance chemical inertness with thermal stability.

Case Study: Extended Service Life in Iron and Steel Ladles

A 2023 field trial with a leading steel producer showed fire brick-lined ladles lasted 4,200 thermal cycles before relining—32% longer than previous materials. The solution reduced annual furnace downtime by 18% and eliminated premature failures from molten metal infiltration. Key factors include:

- Optimized pore structure minimizing slag penetration

- Reactive additives neutralizing ferrous oxides

- Multi-layer zoning for targeted chemical resistance

Similar improvements have been reported in copper smelting and glass tank applications, with maintenance intervals extending from 6 to 9 months under aggressive conditions.

Customization and Proven Applications Across Key Industries

Custom Fire Brick Shapes and Sizes for Complex Furnace Designs

Precision-engineered fire bricks are now essential for complex furnace geometries. Custom-dimensioned bricks with tailored edges and curvature minimize mortar gaps in circular kilns and tapered combustion chambers, reducing heat leakage by 12–18% compared to standard rectangular units (Thermal Engineering Journal 2023).

Tailored Solutions for Boilers, Kilns, and Waste-to-Energy Incinerators

Industry-specific formulations address unique thermal and chemical challenges:

- Boiler Systems: High-alumina variants resist fly ash corrosion in coal-fired plants

- Ceramic Kilns: Low-thermal-mass bricks enable faster firing cycles

- Waste Incinerators: Acid-resistant compositions withstand aggressive flue gases

A 2022 study of 47 waste-to-energy facilities found customized fire bricks extended lining lifespan by 22 months compared to generic alternatives.

Applications in Steel, Aluminum, Cement, and Emerging Sectors

Beyond traditional industries, customized fire bricks support emerging technologies:

- Hydrogen Production: Ultra-dense bricks withstand reducing atmospheres

- Battery Recycling: Enhanced thermal shock resistance for metal recovery furnaces

- Carbon Capture Systems: Modified porosity structures aid CO₂ containment

This evolution positions fire bricks as critical components in both legacy industrial processes and next-generation green infrastructure.

Frequently Asked Questions

What are the main advantages of using fire bricks in industrial furnaces?

Fire bricks offer exceptional thermal insulation, reducing energy loss by 50-65% compared to conventional refractory materials. They also provide superior heat retention, allowing for faster temperature recovery and significantly lowering fuel costs.

How do fire bricks perform under high-temperature conditions?

Fire bricks maintain structural integrity at temperatures up to 1700°C, resisting deformation under prolonged exposure to extreme heat. Their alumina-silicate composition enables them to perform exceptionally well in industrial conditions.

Can fire bricks withstand chemical exposure in industrial environments?

Yes, fire bricks resist chemical wear from molten slag and reactive byproducts, forming protective barriers that reduce chemical degradation. They perform well in both acidic and basic environments.

How customizable are fire bricks for specific industrial needs?

Fire bricks can be custom-engineered for complex furnace designs, with tailored edges and sizes to fit specific requirements and reduce mortar gaps, thereby enhancing thermal efficiency.

Table of Contents

- Unmatched Thermal Insulation and Energy Efficiency

- Reliable High-Temperature Performance Up to 1700°C

- Superior Durability: Mechanical Strength and Thermal Shock Resistance

- Exceptional Corrosion and Chemical Resistance in Harsh Environments

- Customization and Proven Applications Across Key Industries

- Frequently Asked Questions